After more than 60 years after its founding, Alarwool S.L. is a family owned and operated by the same family that founded it. The principal activity is still the manufacture of custom woven wool rich carpets.

At present it not only works with local raw materials but also selects the best wool from around the world to manufacture its carpets, which are installed in cruise liners, casinos and hotel chains worldwide, making Alarwool S.L. one of the world leading custom carpet manufacturing company.

Alarwool S.L manufactures all their carpets according to the most demanding design, colour and quality specifications, working closely with some of the leading design and architectural firms around the world.

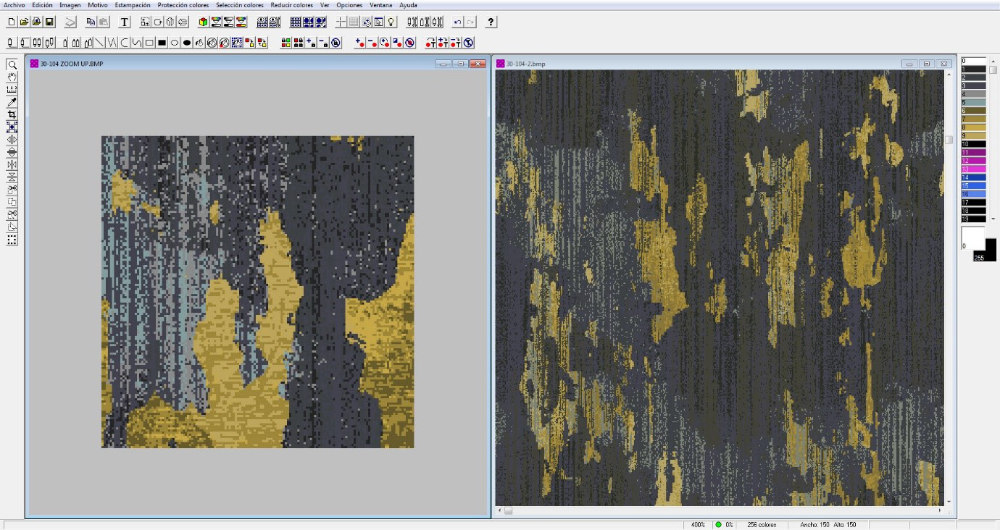

The Alar designers work in the Spanish design studio and use specialised software for vector and digital design. Additionally , the designers often travel to meet with clients for design meetings.

Alar have a production capability to produce over 450,000 square meters of carpets annually, Alarwool S.L. is one of the largest companies manufacturing high quality wool carpets for: Hotels, Casinos and Cruise ships throughout Europe. Alar are fully committed to producing quality floor coverings at competitive prices .The Alar philosophy and work ethic has resulted in gaining the trust of the world’s major hotel chains such as: Four Seasons, Mandarin Oriental, Kempinski, Starwood Hotels, Marriott, Hyatt, IHG, Accor, Hilton, Jumeirah, Carnival Cruises, etc.

Alarwool work on a daily basis with many of the leading interior design and architectural practices : Norman Foster, Philippe Stark, Jacques García, Wilson & Associates, GA International and Rockwell Group are just some of our close collaborators, together with whom we have developed internationally renowned projects for the most prestigious hotels.

Our current customers are for example: Ritz Carlton Hotels, Sheraton, Four Seasons, Hilton, Westin , Hyatt, W Hotels, among many others, all of them representative in their sector for their high demands and commitment with material quality and with the services provided.

All Alar products comply with the required high quality standards and with the strict fire regulations for this type of buildings and as such , Alar products and fully certified and compliant with international standards.

All products manufactured by Alarwool S.L. are primarily aimed at the hospitality and commercial interiors sectors. With this in mind and with over 30 years of experience, we manufacture all our carpets by adapting to relevant certification required by the client whether it be a hotel guest room or circulation area, cinema, theatre, restaurant, casino etc. All the Alar products are fully certified for use in the hospitality, marine and transport markets. Alar wools specialise in producing Axminster, Face to Face, Wilton, and Hand-tufted rugs.

All our carpets are manufactured with 100% virgin wool or 80% wool and 20% nylon blend. Wool carpets are an age old tradition that has been used for thousands of years. The benefits to wool carpet are its´ natural resilience to recover from crushing, which keeps the carpet looking new and fresher for longer periods of time with a natural ability to resist staining and soiling, fire resistant, durable and of course with high levels of comfort. For performance measured over time, wool products are low in cost and high in value.

All the carpet and rugs that we manufacture are custom made , Alar do not keep an inventory or have any running line.

The Alar commitment to quality, a high level of customer service and competitive pricing has gained the trust of major names in the hospitality industry including Ritz-Carlton Hotels, Fairmont Hotels, Millennium Hotels, the Kimpton Group, Sheraton Hotels, and Westin Hotels, Hyatt Hotels, Hilton Hotels, NH Hotels, Sol Melia, W Hotels and many more clients.

Alar carpets are woven on high speed Axminster looms which offer the greatest flexibility, freedom in design and utilise a wide pallets colours. Alarwool S.L. operate a very modern plant in Spain for the manufacture of Axminster, the looms are fully automatic and network-connected to the Design Department.

Axminster manufacturing is very similar to that of any other textile fabric with weft and warp in wool, cotton and jute interweaving in the loom in a solid and efficient manner. At Alarwool we have looms with different widths up to 4 meters, allowing us to adapt to the requirements of each project, eliminating as much as possible waste and reduce installation costs.

The versatility of the Axminster looms allows unlimited production of designs with a maximum of 12 colours which can benefit from smart creel loading which enables Alar to use up to 22 colours in a design. The density of passes and the countless possibilities in terms of design and colours undoubtedly make the carpets woven by Alar , the highest quality in the market. This simple fact is the main reason why Alar products are specified by the major international hotel and cruise liners. Alar are approved suppliers to Starwood, Hilton, Marriott, Fairmont, Four Seasons, Millennium, Kimpton, Sangrila, Mandarin Oriental, Intercontinental, Carnival Cruises, Red Carnation Cruises, Fred Olsen, P&O etc etc.

Carpets that are woven on face-to-face looms have a much greater density in the number of weft yarns and warp so they are extremely wear resistant and have a dimensional stability that is unrivalled in the carpet industry. Similar to Axminster, Face to Face products are classified as a woven carpet. The main difference from any other type of carpet lies in the double structure allowing the manufacture of two carpets simultaneously. Post production, the carpet is cut in half by a blade so that two symmetrical or facing end parts are obtained ( hence the name Face to Face ). This production technique creates carpets with high quality , durabile and are excellent value for money. The production of Face tot Face products are extremely fast and efficient . Additionally, Alar can manufacture Face to Face broadloom rolls up to 4 m wide.

Face-to-face looms allow the manufacture of very sharply defined designs with shaft densities reaching 35 X 80 passes in 10 cm. This allows us to work with much finer wool than those used in any other loom. The result is a carpet of excellent quality, with a density twice that of Wilton or Axminster looms and a definition of design that cannot be compared with any other carpet in the market.

For its many qualities this is an increasingly important product for Alarwool, currently approved for major hotel chains such as Hilton, Millennium, Kimpton Group, Starwood, NH Hotels, Sol Melia Hotels, Park Plaza Hotels, etc.

The carpets woven on our Wilton looms have a special feature compared to other fabric types as it offers the possibility of manufacturing the plush in cut pile and loop allowing the development of unique and elegant designs and textile figures. Technically, Wilton looms the wool threads which run continuously through the backing of the tissue, appearing on the surface of the carpet when requested by the design; the weft and warp intertwine with the plush threads on the loom forming a fabric of great consistency and solidity.

Its main attractiveness lies in the possibility of developing designs even in a single colour with different cut and loop combinations. The carpet is no longer a plain fabric, it acquires texture and becomes three-dimensional contributing to the overall design of any room.

The Alarwool carpet collection represents the best of tradition and craftsmanship. All Alar handmade rugs are 100% handmade and not machine produced and are the perfect luxury complement for any 5 star hotel . Each hand tufted carpet is uniquely produced and as such, strictly manufactured to order and in accordace to the meticulous instructions of our customers and their designers.

Made from pure wool of the highest quality, the design possibilities are endless given there are no limits on size, number of colours and design. Among other things it is possible to mix different materials -such as viscose or silk-, perform cutting, loop, varying hair heights, carry out irregular or oval shapes, etc.

Alar Color IT Design

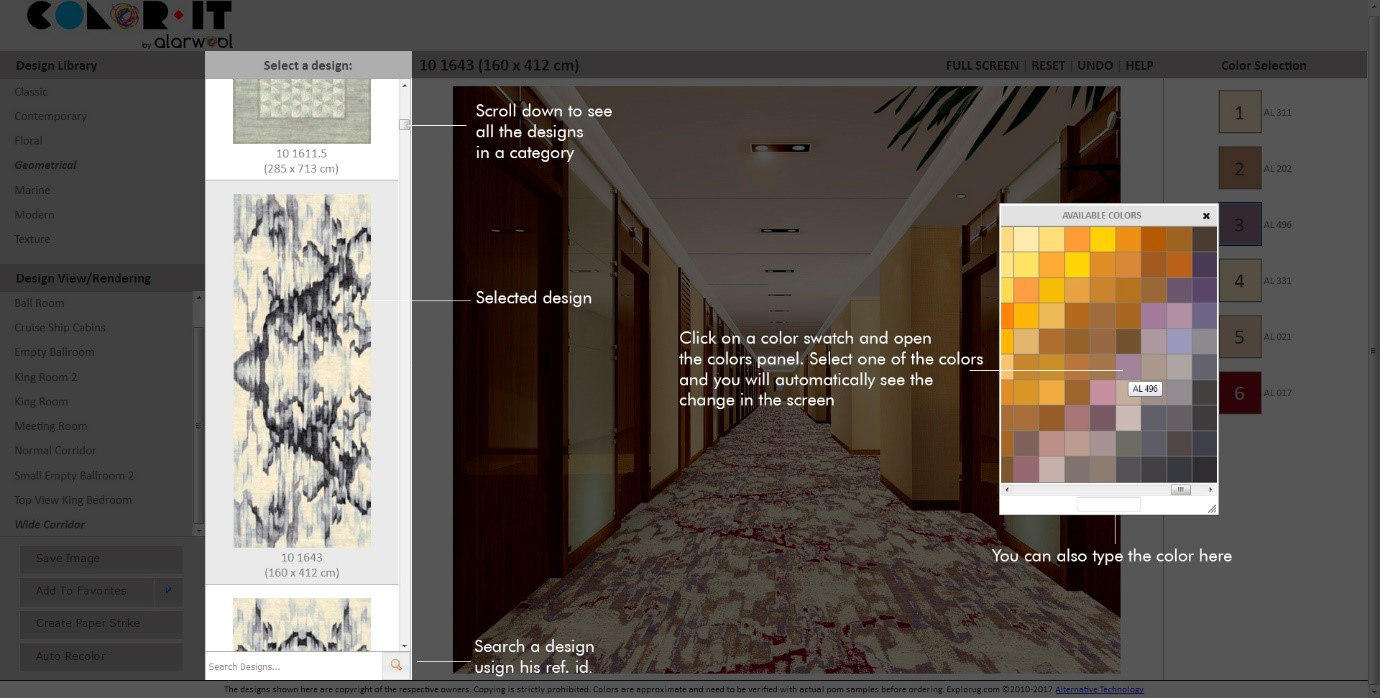

For many years Alar have worked with designers who create fabulous interiors . As part of the support that Alar provide , Alar have created a design section of their website where designers can start the design process by selecting colours and room settings. Within Color IT , designers have access to an endless amount of colour and design possibilities .

Color-IT: Interactive design tool for designers

Color-IT is a very simple colour tool developed by Alarwool to help our clients to customise and visualise their carpet designs in real-time and in a very efficient way. This program allows access to a very exclusive library with hundreds of designs grouped by categories where each one can be re-coloured as required. If you already have an Alarwool colour pom box, you will be able to check how your colour combination works and if you want to make any change you can easily do it. ( Ask RGI for a colour Pom box)

The program also has an option that automatically re-colours the design instantly creating thousands of versions of the same idea with only a click. Finally, you can place the chosen design in a real space thanks to the powerful rendering tool that is included in the software. No matter if it’s a ballroom, a guestroom, a corridor or a meeting room… Color-It offers to the user different environments to check on his own how the design is adapting to every room.

Access to the Color-iT program requires an access code – please contact RGI Agency for more information.

Alarwool is an innovative company with continual evolution into new markets . Utilising the expertise and technical knowledge within Alar, Alarwool entered the railway interiors sector and have partnered with Renfe and Siemens. Additionally : Alar have developed specialist products for MP Yacht which specialises in luxury trains and yacht interiors.

Alarwool is one of the few companies in Europe that has produced specialised products that can withstand the intense traffic of transport interiors and as such have achieved the relevant certification (EN 45545-2:2013+A1:2015) including ISO 9239-1 CFE, ISO 5660-1, and ISO 5659-2 being the final level classification R10-HL2.

Alarwool have successfully produced products for RENFE for use within their passenger rail carriages . The design created was in a geometric design using a grey colour pallet for the corridor areas where heavy traffic is present.

MP-Yacht group started designing transport interiors in 1984 and offers its clients a complete service that includes the initial design up to the complete equipment required for luxury yachts and trains. In 2017 Alarwool produced, in collaboration with MP Yacht, several rugs and carpet areas in Hand Tufted quality for the Talgo trains which operate in the Middle East. The design was inspired and created using oriental architecture as the basis for the design and colours used.

The current over exploitation of the planet compromises sustainability and the available resources for the future generations. In order to ensure environmental preservation, recovery of natural areas, water and waste administration, we all need the commitment of all the parties involved , we also require the promotion and implementation of specific policies oriented towards sustainability.

At Alarwool we are fully aware of the importance of developing our business activity within a framework of respect and sensitivity towards the environment. Therefore Alarwool Executive Management establishes an integrated system of quality and environmental management, from which we work to minimise the environmental impact that our activity produces.

Alar Wools have developed a program of best environmental practices in order to save resources and consumption and to minimise the management of any waste products from our production process.

More than 90 % of our raw materials are obtained directly from nature, such as wool and cotton. Our lambswool comes from Spain, England, France, New Zealand…. always from alive specimens, which are subjected to the process of shearing once per year. This process is made with scissors or special shearing machines that guarantee that the animal does not suffer any harm as well as maximum respect and care for the valuable wool fibres.

In a later process, the wool is mixed with nylon fibres in a percentage of 80 %-20% in order to give added strength and abrasion resistance. All the nylon that we use for these mixtures is recycled, reducing by 50% the emissions of CO2 into the atmosphere .1000Kg of Recycled Nylon it is equivalent to 1,424kg less of CO2, which it is the same energy that one bulb consumes if on for 401,500 hours.

In the sector of transport Alarwool is committed with shipments optimisation with the target of minimising the environmental and economic impact and maintaining the growth of the welfare state without overexploiting the resources of the Earth.

Alar have focused upon how we can save our energy consumption by finding alternative sources of power generation. Alar have designing energy-efficient production facilities and infrastructure. Alarwool’ s commitment to the environment is strong, Alar have a sister company called Luzalar which is devoted to the production of energy through a hydroelectric power station located in the Spanish province of Palencia. By investing in renewable energy, Alar have minimised the environmental impact created by carpet production .Today Alar generates more energy than consumed in our facilities.

The importance of managing the resources properly is such that several international agreements and World Conferences on the Environment, such as the one of Rio in 1992, have addressed the issue.